12V Guru – Optimising your Solar Power System

Solar Panels installed on your vehicle roof? Our 12V Guru discusses how to optimise their performance in place of buying more panels

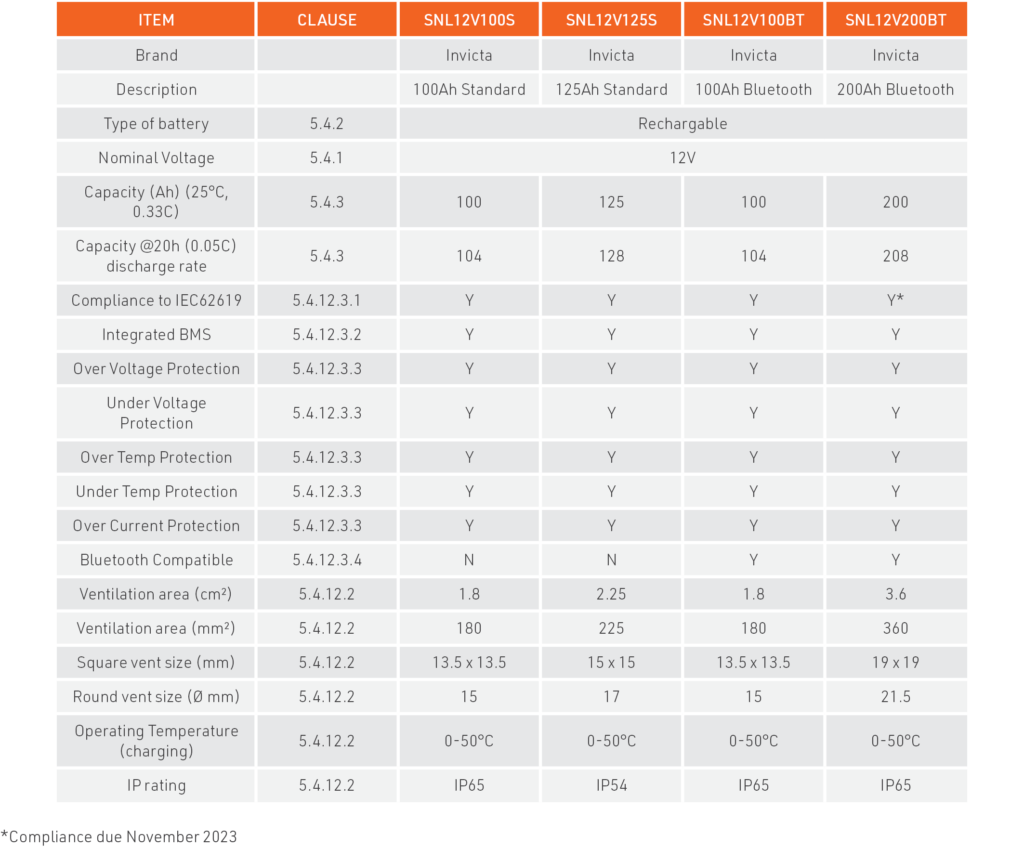

This is a guide to help understand the requirements of the new standard in relation to lithium battery installation in Australian and New Zealand RVs. It also details out the specific recommendations for the BMPRO Invicta range of lithium batteries to ensure you meet the requirements of the standard.

This released standard applies to new builds from November 2023.

Clause 5.4.12.3.1 Requirements

The battery management safety system is designed to protect the lithium ion battery from potentially damaging situations. This includes the battery management safety system and cells, the whole battery. The BMPRO Invicta batteries referenced in section 9 of this document have IEC certification which applies to the whole battery.

In some cases only the cells are certified to IEC62619. If only the cells are certified it means the key safety component of the BMS (Battery Management System of the battery) and how it interacts and manages the cells has not been considered and reviewed and therefore complies with IEC62619. This is especially important regarding battery cell propagation and thermal runaway.

CELL VS BATTERY

CELL: A cell is a single encased electrochemical unit.

BATTERY: Battery means two or more cells which are electrically connected together and fitted with devices necessary for use, for example, case, terminals, marking and protective devices.

A single cell battery is considered a “cell”, regardless of whether the unit is termed a “battery” or a “single cell battery”. ref. UN38.3

It’s important to ensure that the battery manufacturer or supplier can provide the certificate of compliance to verify that the batteries are compliant to IEC 62619.

The whole certificate of compliance is available on the individual battery product pages on the BMPRO website.

5.4.12.3.4 Monitoring device

Each battery (or bank of batteries) shall be monitored via a battery monitor designed formanaging lithium ion batteries. The monitor shall display the state of charge (SoC) and may display voltage. Communications with the monitor may be by wired or wireless connection direct to the battery management safety systems.

The parameters displayed in the BMPRO Invicta app include State of Charge (SoC), voltage, capacity, battery status and temperature.

For non-Bluetooth compatible batteries, BMPRO offers a range of battery monitoring devices and Power Management Systems which also monitor and maintain batteries and display battery data via a controller, wired display or smartphone app. For more information on BMPRO monitoring products, please refer to our website.

5.4.10.2 Metallic services line

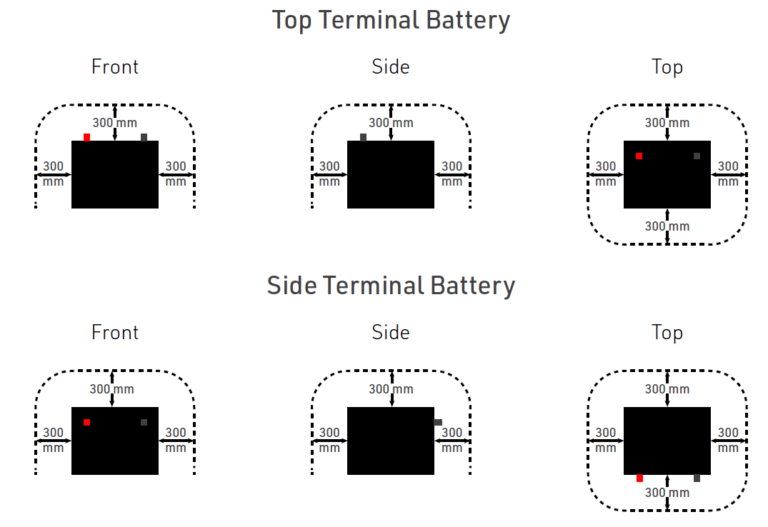

In compliance with clause 5.4.10.2, battery installations are required to be a minimum of 300mm away from gas, diesel, water and other fuel lines. The exclusion area is limited by the sides of the battery box or compartment. This applies to the horizontal and vertical plane of the battery surface containing terminals. If the exclusion area is not able to be achieved, dielectric material is to be used to protect against accidental short circuits.

Individual batteries or battery banks are required to be protected against overload and short circuit by fuses or circuit breakers to be installed on the positive pole. Ensure the location of the protective device complies with clauses 5.4.7.2 and 5.4.10.1.

Protection devices as detailed in Clause 5.4.7.1 shall be accessible, protected against accidental damage and installed in one of the following locations:

(a) within 200 mm of the battery terminals; or

(b) directly outside the battery compartment; or

(c) 1.0 m from the battery terminals, provided each conductor is contained within a protective covering, such as a sheathing, conduit or cable trucking for its entire length from battery terminals to the circuit protective device, to reduce the risk of mechanical damage.

Overcurrent protective devices shall not be fitted in a fuel storage compartment or fuel storage housing intended for the storage of LP Gas cylinders.

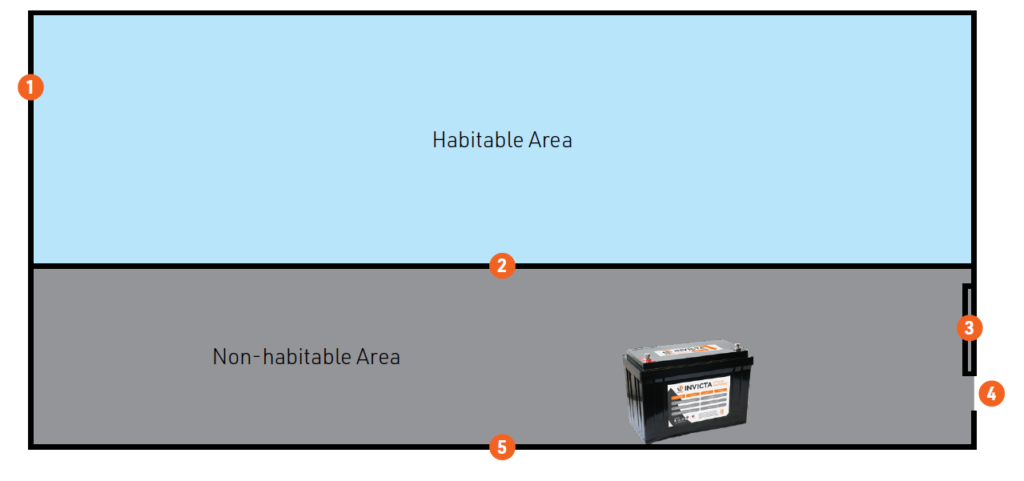

Lithium ion batteries shall:

(a) be installed externally, i.e. behind a wall, compartment or barrier that prevents the egress of gases into the habitable structure; and

(b) not enter the habitable area of the structure; and

(c) be installed to operate within the manufacturer’s defined operating temperatures, including IP rating; and

(d) be installed in a suitable battery container where the battery manufacturer has not provided encapsulated cells.

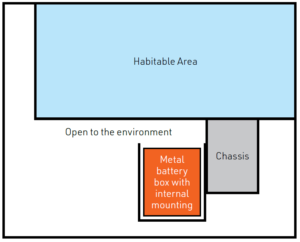

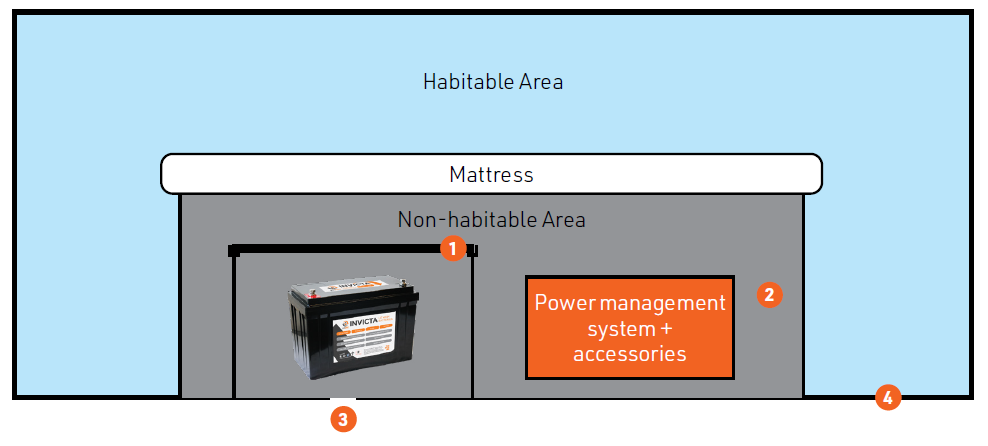

Batteries are required to be installed so that any vented gases are unable to enter the habitable area of the recreational vehicle.

For batteries installed in an enclosed area, such as behind a wall, under the bed, in a cupboard or under a seat, the battery installation is required to be in a sealed box or container which is vented to the outside of the RV. Cables into the battery box or container must be sealed by cable glands or similar. Refer to the Specifications Table in section 8 which details the ventilation area requirements per battery.

For installations external to the recreational vehicle body the battery should be protected from physical impact by a box or container which is vented to the outside of the RV.

In addition to the location of where lithium batteries can be installed, care should be taken to comply to other aspects of the standard.

This includes but is not limited to the below:

Materials used for construction of the battery compartment should protect the battery from accidental damage, meeting the criteria defined in this document and allowing the battery to operate within the BMPRO defined operating conditions, temperatures and IP rating.

If installed within these criteria it is deemed sufficient prevention for thermal runaway events.

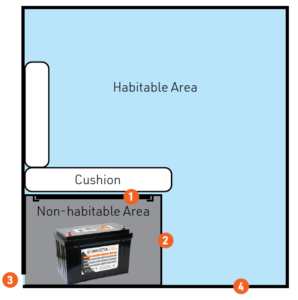

The following examples are guidelines on how the batteries could be installed. It is up to the manufacturer of the caravan to determine the most suitable to meet the Clause 5.4.12.2 detailed in the section above.

Refer to the Specification Table in section 8 for IP rating specifications which may determine if the battery can safely be installed externally to the RV for the intended use of the RV. For example, if the RV will be taken on river crossings where the battery is likely to be temporarily and less than 200mm of being submerged, the battery would need to be IP65 rated to be suitable for this application. This is similar to a motor vehicle which is rating IP65 on wiring harnesses and some components.

A separate sealed compartment is recommended, with venting and sealed lid, along with cable glands out of the box.

In this drawing, the area under a seat is being used as the sealed compartment. If this is not achievable then an additional sealed compartment is necessary as per the Under Bed concept above.

Ensure overcurrent protective devices are not fitted in a fuel storage compartment or fuel storage housing intended for the storage of LP gas cylinders.

In this area the Tunnel Boot is a large area, which can be sealed, however it may be necessary to potentially section the area off if using this area for the battery. Ensure the battery is protected from potential impact and mechanical damage from any goods stored in the tunnel boot.

Any questions in relation to how BMPRO Invicta Lithium batteries comply to the standards can be directed to customerservice@teambmpro.com.au.

For members of Caravan Industry Association Australia access is available through Caravan Industry Association of Australia and the i2i Platform, AS/NZS 3001.2:2022 is now available to view and download. For other businesses to access the standards they are available for purchase.

It is important to note that this document does not provide an exhaustive list of changes to the standard. It is strongly recommended that industry businesses make their own investigations and explore the changes to AS/NZS 3001.2:2022 with regard to the recreational vehicles they

are producing. It is also important to ensure that the relevant personnel (e.g. contract or staff electricians, vehicle designers etc.) within your business are up to date with these changes.

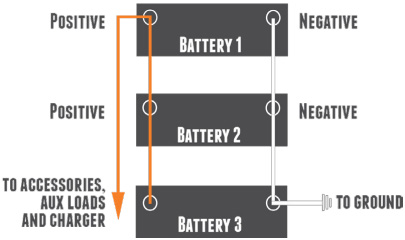

All BMPRO Invicta lithium batteries can be configured into a parallel configuration up to 4 units in parallel under the conditions outlined below:

Clause 1.5.2.1 allows for installations to be repaired and replaced without inacting the requirements of the new standard.

Note however, repairs or replacements need comply to the standards applicable at the time of installation or to AS/ANZ 3000 at a minimum, which does not require the sealed compartment with venting.

Solar Panels installed on your vehicle roof? Our 12V Guru discusses how to optimise their performance in place of buying more panels

Looking at installing your own 12V products such as a DC-DC charger and shunt? Our 12V Guru discusses connectors and what you need to know here

This is a guide to help understand the requirements of the new standard in relation to lithium battery

© 2020